- Ingersoll Machine Tools Inc. and Innse Berardi will have two booths at the show, participating in the Emerging Technology Center and a dedicated space in the machining section, South Hall

Ingersoll/Innse-Berardi are two of world’s largest and most advanced builders of high-tech machine tools and production systems.

Projects the group is involved with include Artemis, man’s return to the Moon and onwards to Mars, Rosenberg space habitation units, Giant Magellan Telescope, the most powerful telescope on Earth.

Also working on next generation defense vehicles utilizing MasterPrint®; 3D printing and additive manufacture of aerospace components; automated fiber placement and large-scale polymer printing, utilizing MasterPrint®, Mongoose®, and Hawk™.

- Expert in digitalization, process optimization, and technology transfer

Rockford (IL), 12 September 2022 - Manufacturing technology innovators from around the globe are converging on IMTS (The International Manufacturing Technology Show, McCormick Place, Chicago, September 12-17, 2022) to discover the latest developments in digital, additive, and traditional subtractive manufacturing and automation.

Ingersoll Machine Tools and sister company Innse-Berardi will have two booths at this important show.

At the Emerging Technology Center (Booth no. 236700), the focus is on the forward-thinking manufacturing advances supporting projects for long-term deep space exploration. Ingersoll will be 3D-printing the door of the Rosenberg space habitation module with the Masterprint® Robotic – a high-tech home-from-home needed as humankind returns to the surface of the Moon invented by the students from the Institut auf dem Rosenberg of St. Gallen. Ingersoll was contracted by SAGA Space Architects to print a full-scale space habitat that is one part of a 2.5 storey habitat. The full structure has a functional interior to support residency on the moon and the scaled section on show will be one of the most striking demonstrations of additive manufacturing that industry leaders will have ever seen.

Alongside this will be a profile of the Giant Magellan Telescope, the most powerful telescope on Earth, and the innovative ground-breaking components Ingersoll make for it. At 22 stories tall and weighing 4,800 tons, the GMT will be 10x more powerful than Hubble, with many of its parts machined to nanometer precision.

Ingersoll’s booth (no. 338004) will be in IMTS’s machining section, South Hall, where its craftmanship and applications expertise will be showcased with the milling machines used to make the Orion space capsule. This important component of NASA’s Artemis mission will carry the next generation of brave astronauts into orbit, to the Moon and beyond, then return them safely to Earth.

While these projects are pushing man’s achievements to scarcely imaginable new heights, Ingersoll will also be demonstrating how these new technologies are directly and easily transferable to other, Earthbound, sectors, such as defense, aerospace, manufacturing, maritime engineering, healthcare, and construction

Ingersoll/Innse-Berardi are specialists in the engineering, production, and commissioning of high-performance, technically advanced machine tools for highly demanding industries, including energy, transportation, aeronautics, and aerospace. Their solutions include large vertical and horizontal milling and boring machines, multitasking work centers (in either hydrostatic or mechanical configurations) and the production of large, specialized machines dedicated to specific applications.

With an army of specialists dedicated to pushing the boundaries of digitalization of manufacturing processes to new heights and to developing the new technologies that will define the standards of tomorrow, Ingersoll/Innse-Berardi together are an ideal strategic and technological partner, capable of supporting customers with a complete turnkey service in a wide range of highly demanding industries.

High-tech machines demonstrations Ingersoll/Innse-Berardi will have on actual or virtual display at IMTS will include:

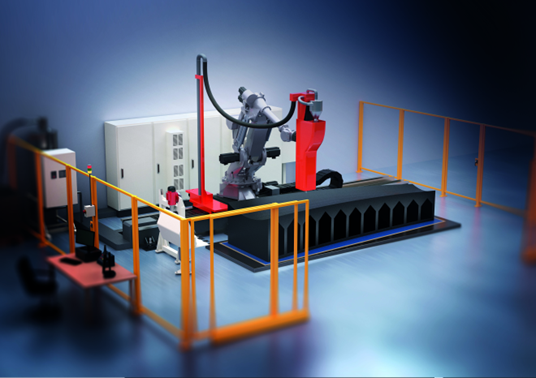

- MasterPrint® Robotic one of the world’s most advanced additive and milling solutions, that allows defense vehicles and aerospace, space, and navel, solutions to be produced to a near net shape in both metal and polymer based.

- PowerMax™, with enhanced capabilities to quickly machine complex parts in aluminum and titanium.

- Aries, the high-speed, top performance boring and milling center with linear guideways and roller pads, suitable for 3 and full 5 axes machining.

- Atlas, the high-speed vertical milling center, with linear rolling guideways with the Innse-Berardi’s innovative flexible design.

- A demonstration of both the DRM (Digital Remote Maintenance) and CyberMES digital platforms, Camozzi Digital & Mechatronics’s state-of-the-art IIoT and cloud computing solutions that improve the performance and lower operating costs of its machine tools. DRM draws data from sensors installed in critical parts of the machine that monitor key operating parameters to identify machine errors in real-time. CyberMES simplifies, speeds up and makes production management control more efficient, automating business processes and supporting decision-making.